HISTORY OF THE NORFOLK NAVY YARD IN WORLD WAR II

By

Arthur Sydnor Barksdale, Jr.

Lieutenant Commander, USNR

Portsmouth, VA 1945

Table of Contents

(Continued)

Chapter VI: Expansion During the Emergency and War

Drydock No. 8 and Area

Inspection by the President

Other New Buildings and Shop Improvement

St. Helena

Barracks and Quarters

Expansion of Supply and Storage Areas

Growth of Telephone System

Summary

Chapter VII: Yard Security

Air Raid Defenses

Enlargement of Police DivisionPart Three: Production

Chapter VIII: Over-All War Achievement

Comparison of Construction, Repair and Manufacturing

Dollar Value of Production

Accounting Controls

Chapter IX: Repair

Sixty-eight Hundred Ships

Planning and Production Problems

CMP and Material Redistribution

Repair of British and Other Allied Ships

Major Battle Damage Repair

Conversion and Alteration

Fitting Out and Commissioning

* * * * * * * * * *

VI. EXPANSION DURING THE EMERGENCY AND WAR

Drydock No. 8 and Area

Closely paralleling the speed-up of national defense which followed the sweep of the Germans through Europe in the summer of 1940, major expansion of the Yard to the south was undertaken. This development centered around Drydock No. 8.

With the Navy planning vast enlargement of the Fleet, it became obvious that greatly expanded new construction facilities must be provided. As early as 1939 construction of an additional set of buildingways had been asked for by the Navy Yard management and interested community leaders. These plans actually reached the point where test borings were made between the destroyer Buildingways and Drydock No. 4 to determine the suitability of this site.

Original plans for expansion of the Navy Yard after World War I had envisioned use of this location for another drydock which would have been No. 5, but instead the site was utilized for the Sub-Assembly Building No. 261 because of the pressing need for pre-fabrication facilities adjacent to the existing ways, and it was decided to locate the new shipbuilding facilities in the southern portion of the Yard. It is interesting to note that the Navy Yard still has no Drydock No. 5.

Because of increasing ship tonnages it was decided that a building dock would be more satisfactory than a second set of buildingways. A building dock was favored over ways for the reason that large vessels could be launched more easily and with less danger than from launching ways. In addition a building dock could also be used for repair work, providing facilities for handling the largest ships afloat or planned. Although a dock would cost considerably more than ways, its availability for repair as well as construction make it more economical in the long run. At the beginning of the war in Europe there were only three drydocks on the East Coast capable of handling 45,000-ton vessels, one at South Boston, one at Philadelphia and No. 4 at Norfolk.

As has already been noted, the southern portion of the reservation beyond Pier 5 was largely marsh and water, and the construction of Drydock 8 resulted in the reclamation of this land providing for the building up of a whole new section of the Yard.

Drydock No. 8, which was built at the same time that a similar dock was being built in Philadelphia, was begun in July 1940 and completed in July 1942. (N16(89); Contract No. NOY 4100)

The contract for the work on a cost-plus-a-fixed-fee basis was let by the Bureau of Yards and Docks to Spencer, White and Prentiss, Incorporated, Foley Brothers, Incorporated, and Merritt-Chapman & Scott, Corporation, all of New York on June 26, 1940. It provided for construction of two docks, the one at Norfolk and the one at Philadelphia. The contract for the two building docks, which was approved on June 27, 1940, by the President, carried an estimated cost of $17,000,000 for the projects. This figure was for the construction of the docks themselves and was exclusive of equipment.

Drydock No. 8 was built entirely under water. The excavation began at the point where Back Creek joined the river and it was pushed inland roughly conforming to the course of the creek. After the excavation was completed, concrete forms for the sides of the dock were placed under the water and the concrete poured into them.

Dredging operations were carried out with what was said to be the largest and most powerful diesel electric floating dredge then in use. A basin 70 feet below the surface of the water was dug, the first time that dipper dredging had ever been used for such a depth. The dipper of the dredge removed 16 cubic yards of muck and earth at each scoop, the rate being approximately 16,000 cubic yards every 24 hours. The mud and dredged material was pumped to what is now the Yard dump and incinerator area to fill in the swamp along Paradise Creek, and some was hauled in barges out to Cape Henry where it was disposed of.

After the first major operation of dredging out the basin was accomplished, thousands of steel piles were driven into the soft earth bottom upon which the floor of the dock was to be laid. A two-foot layer of gravel was spread over the entire bottom area and powerful pile driving rigs then drove 60-foot long H Beam piles by the thousands until their tops were 65 feet below the water level.

Upon these piles were next lowered steel trusses which formed, section by section, the bottom of the dock. Divers groping in the watery darkness seated the steel trusses, which were really bottomless boxes for the concrete, on the piles. Into these "boxes" was poured the concrete by using tremies or pipes. The trusses reinforced the concrete against the tremendous uplifting pressures of the water and at the same time provided sufficient foundation for the support of heavy ships.

Twenty and a half feet of concrete was poured into the bottom of the dock and the walls were filled to a 22-foot thickness, all of this concrete reinforced with thousands of tons of steel.

A huge concrete mixing plant was set up for the job. The plant received its sand and stone by barge which was unloaded into huge steel bins equipped with heating devices so that the work could proceed without delay in freezing weather. From these storage hoppers long lines of rubber conveyor belts carried the sand and stone to enclosed bins under which were set the weighing devices which proportioned the materials for the three concrete mixers. These mixers discharged into four pumping machines which forced the concrete through four 8-inch pipe lines to the tremie concrete barge. The liquid concrete was distributed from the barge through the tremie pipes which passed it into the forms far below the water.

On August 16, 1941, the huge new drydock was pumped out for the first time. First, a coffer dam was built across the open end of the dock to keep the river out and permit the emptying of the basin. As the murky water of Back Creek was pumped out, the structure which had been taking shape beneath the water became visible for the first time.

The rough underwater concrete was then cleaned off and the smooth layers of concrete lining with which the dock was finished were applied.

Meantime, a caisson gate was built and fitted across the open end of the dock inside of the coffer dam. The building of the dock was completed with the filling in of the area outside its concrete walls with thousands of cubic yards of earth excavated on the Maupin farm property near Cradock and hauled to the Navy Yard to form solid ground where once had been water.

At the entrance to the dock, which goes back from the river at an angle to the Piers in that vicinity, the river was dredged to form a large turning basin.

After filling in around the dock, the auxiliary services necessary to its operation were installed -- submerged pumps for draining it, water and compressed air lines, electric conduits, etc.

The completed dock was 1,100 feet long and 150 feet wide, with a depth of 47 feet. It is thus large enough to take any ship now afloat.

With the completion of the new drydock, the waterfront was further extended by the construction of Pier 6 and the quay walls forming Berths 42 and 43, completing the reclamation and development of the southern area of the Yard.

The development was completed in 1942 and 1943 with the installation of streets, railroad tracks, the necessary crane services and buildings and shops and office space. Serving the dock are six 20-ton and two 75-ton traveling jib cranes, while two additional 25-ton Hammerhead cranes serve Pier 6 and one 75-ton Hammerhead crane serves Berths 42 and 43. The track arrangement is such that the cranes can be moved to any point along the quay dock side or pier.

The two major new buildings in the area are Building 298, a field shop building and new construction office, and Building 369, Shipfitter and Assembly Shop in which was also placed the Sail Loft and Optical Shop.

The latter building was erected south of the drydock in order to provide steel fabrication facilities primarily for new construction.

The building, one of the largest in the Yard, is 100 feet wide and 1,100 feet long, with a second floor originally planned as a mold loft. Its excellent bridge crane facilities permit a very heavy assembly to be welded complete and carried out to the drydock where it is picked up by the 75 ton traveling jib cranes and placed in the dock. The cranes pass out of the west end of the building and service an area in the open space approximately 600 feet long where much fabricated material is assembled.

To provide steel pickling facilities adjacent to this shop, new pickling tanks for both plates and shapes were constructed on the southside of the building and special bridge cranes provided to handle the material in and out of the pickling tanks. For the storage of structural steel while awaiting fabrication, a large steel storage arrangement was also constructed south of this building, serviced by four Gantry-type cranes.

In this connection it should be noted that, in order to provide additional facilities for the handling and pickling of structural steel for new construction and for repair work at a point close to the main structural steel ship in Bldg. 163, an additional steel storage area and pickling tanks for plates and shapes was also constructed southeast of Bldg. 268. Adjacent to this steel storage, a fabrication area for structural shapes was laid out and equipped so that approximately 90 per cent of all structural shapes going into ship construction are fabricated out in the open adjacent to the steel storage, thereby eliminating the costly and time-consuming handling of such material into the Shipfitter Shop, which was the practice for many years. This steel storage and pickling arrangement is serviced by four Gantry cranes. It is understood that these Gantry cranes are the first cranes of this type to be adopted in Navy Yards and they have proven to be very economical and rapid in the handling of materials.

Inspection by the President

In the midst of the expansion of the summer of 1940, President Roosevelt visited the Navy Yard on a tour of inspection. The Commander-in-Chief was accompanied by the new Secretary of the Navy, Frank Knox, whom he had appointed upon the resignation of Secretary Edison early in July; Representative Carl Vinson, Chairman of the House Naval Affairs Committee; Secretary of Commerce Harry Hopkins; Chairman Sheppard of the Senate Military Committee; Captain Daniel J. Callaghan, USN, Naval Aide to the President, who was killed in the Battle of Guadalcanal and for whom the Navy Yard's Callaghan Center was subsequently named; and other high ranking Naval Officers and members of the White House Staff.

The President's visit occurred on July 29, 1940. He came to the Yard aboard the yacht POTOMAC which was docked at Berth 5 in wet slip No. 1. His tour through the Yard was greeted with widespread enthusiasm by employees of the plant, especially because of the increasing tempo of national defense in that important summer.

Accompanied by Admiral Simons and the District Commandant, Rear Admiral J. K. Taussig, USN, the President was shown the beginning of construction on Drydock 8, the recently completed Pier 5, the new Turret Assembly Plant, the ALABAMA then under construction on the battleship ways, and the various shop extension and improvements which were then being affected.

A feature of the visit was a report by the Commandant to the President on the expansion of the Navy Yard which was occurring at that time which was broadcast to the Nation as an evidence of growing defense activities.

The President, who had visited the Yard previously during World War I when he was Assistant Secretary of the Navy, commented on "The splendid work being done, not only to facilities new construction but also repair work." Referring to the Yard when he was Assistant Secretary, he said it was "one of the most important we had in the Navy."11

11 This account of the President's visit is taken from the Nfk.Vgn.Pilot, 30 July 1940.

Admiral Simons' report to the President is quoted herewith for the general picture which it gives of the activity in the Navy Yard at that time. The matters of housing and employment which the Commandant mentioned will be discussed in later chapters of this history:

"Mr. President, since September 1939 we have expanded, I estimate, some fifty millions of money in preparing to do our share in meeting this national emergency. These expenditures are rapidly increasing in volume. Since last September this Navy Yard has increased it force of regular labor by 50 per cent. Since last September this Navy Yard has added to its resources about eighteen million dollars worth of buildings, tools, docks and equipment. Since last September the requirements of this Navy Yard have caused to be built and contracted for over two thousand new homes for its workers, about ten million dollars' worth of houses. Sine last September we have exhausted the various brackets of skilled labor and have resorted to intensive training by apprentice and helper systems; we have trebled our allowed number of trainees since September, and I believe we will soon have to double the number we have.

"I will show you this morning on your tour of the Yard our major improvements, such as:

Construction and equipment of new Pier Construction of new Extension to Foundry and Structural Shop New Turret Shop and 35-ton Crane Additions Power Generating and Distributing Systems New Sub-Assembly Shop New Storehouse Addition to Machine Shop Machine Tools, Equipment, Cranes, etc. Miscellaneous Projects by Yard Labor and WPA Emergency Wards Naval Hospital Shipbuilding Dock and Accessories TOTAL

"In reference to the housing of our rapidly growing force, this housing was inadequate last September. Since then we have built or contracted for:600 units for rental to low-paid employees. City of Portsmouth and U.S.H.A., $2,000,000 project

400 units costing $2,500-$3,500 at Simonsdale, Norfolk County, F. H. A.

163 units costing $3,500 in Cradock Extension, F.H.A.

150 units costing $2,500 at Pinners Point, City of Portsmouth

200 units costing $4,000 to $6,000 at Greenacres and Pincrest, private contractor

250 units costing $4,000 to $5,000 in Portsmouth and Norfolk County by numerous small builders, F.H.A.

200 units for low rentals being planned,

100 units for high rental being planned.

2,123 TOTAL UNITS"In closing, I wish to thank you, Mr. President, for your ready and unfailing help to us here at Norfolk Navy Yard in our efforts to build up to meet the emergency, and I take this occasion to thank the members of your staff in the Civil Service, the R.F.C., the F.H.A., the U.S.H.A., the W.P.A., and the P.W.A., for their ready and willing cooperation. As far as I am concerned, I might add that the members of the Senate and Congress with whom I have worked, have done everything possible to help this Yard rise, and we could not have gone so far towards our goal without their assistance."

Other New Buildings and Shop Improvements12

12 For additional details on shops, see His.Memos, Shops, A12(3); also NyNor Indus. Dept. Manual, Ch. 10, Shops.

Coincident with the work on Drydock No. 8 during 1940 and 1941, the Yard in keeping pace with the increasing demands of National Defense undertook additional shop improvements and erected a number of major new shop buildings, among them a new Labor Board Building No. 254, (Ch. XIV; Sec. 2), a new Material Assembly Building No. 268, an additional Paint Factory Building No. 275, a modern Main Dispensary and a new restaurant building No. 265.

Preceding these new buildings, an important new extension was added to the Inside Machine Shop, Bldg. 171, to which Admiral Simons referred to in his report to the President quoted above, an addition which virtually doubled the capacity of this shop. This increase in Shop 31's capacity was made necessary by the growing volume of machinery work then coming to the Yard.

This work which began in July 1940, the second extension to the building, was completed in June 1941 consisting of two additional bays on the north side of the building, each 65 feet wide and three stories high. The addition to Shop 31 of such large proportions necessitated a complete rearrangement and regrouping of machine tools in order to streamline the shop to modern production methods. Approximately $10,000,000 was expended for the purchase and installation of modern machine tools. 13

13 See also His. Memos, Shop, A12(3).

As a result of these changes, the Norfolk Navy Yard's Inside Machine Shop is said by Naval authorities to be probably the most modern marine machine shop on the Atlantic Coast, and its manufacture to turbine blades, high pressure steam valves, arresting gears for aircraft carriers, Diesel engines for motor boats, spare turbines for carriers, cruisers, destroyers, and destroyer escorts was a major factor in enabling the Norfolk Navy Yard to serve the Fleet. In addition there are a large number of minor items which this shop manufactured during the emergency because of the inability to obtain satisfactory deliveries from private contractors.

As a result of this shop's being tooled to modern production methods, the Yard was in a position to take on a considerable amount of heavy parts for other Navy Yards and for private contractors who held contracts with the Navy, and thereby relieve the strain on such facilities in other localities. The Yard through this facility was able to come to the rescue of the heavy machine tool industry and made a large number of heavy machine tool castings.

The erection of the addition to Bldg. No. 171 meant that the Co-Op Restaurant Building (Ch. XXI) which had occupied a portion of the space required for the addition had to be removed and a new Restaurant Building No. 265 was erected in the fall of 1940.

During 1941 a large new Material Assembly Building, No. 268, was erected. It was begun in January 1941 and completed by the end of the year. Although constructed primarily as an Industrial Department storehouse, this building was taken over as an auxiliary to the Inside and Outside Machine Shops, X31 and X38, and used as an erection and assembly shop. Half of this building was devoted to the repair of ordnance equipment such as guns, gun mounts and other gear.

An additional ordnance storehouse, Bldg. 278, was also constructed in the northern section of the Yard near the turret assembly plant during 1942.

On April 28, 1941, construction of a new building to house the Paint and Varnish Factory and Paint Laboratory, Bldg No. 275, was started. For a number of years the Norfolk Navy Yard had been a manufacturing center for Navy paints. Ships of the Fleet operating in the Atlantic waters and East Coast Navy Yards had long been supplied with paint and varnish manufactured at Norfolk, and due to the enormous increase in the number of ships to be painted in the early days of the emergency, it became necessary to supplement the paint manufacturing facilities.

The new buildings not only provided additional space but allowed the rearranging and modernizing of the equipment and the existing paint factory, Bldg. No 262, as well. The Yard then redoubled its efforts in the development of modern paints to meet the demands of the emergency, with the result that the paint chemists of the Norfolk Navy Yard developed hot and cold plastic paints for ships' bottoms which permitted vessels to remain at sea from two to three times as long as they did prior to the war when using the older types of ships' bottom paints.

The completion of Building No 275 permitted the installation of a modern paint research laboratory on its top floor where research in paints could be constantly pursued. (His.Memos.Paint Lab., A12(3)).

Further carrying out the expansion and new building program of 1941 was the construction of a new and up-to-date Main Dispensary, No. 277, a facility especially designed to handle industrial accidents and to care for civilian and Naval personnel of the Yard. The new structure, fireproof and air conditioned, was located on Mayo Avenue in as central a location as it was possible to obtain (Ch. IV; Sec. 11).

The building, of modern functional design, houses both medical and dental departments and is fitted with the latest type of equipment. Begun in August 1941, it was completed in the early summer of 1942 and dedicated on July 1, coincident with the dedication of Callaghan Center, (Sec. 5).

In addition to the buildings already mentioned, a storehouse, Bldg. 297; two radio material buildings, No. 11A and No. 15A; a salvage storage building No. 372 and the storage buildings Nos. 377-384 at Southgate terminal (Sec. 6) were constructed in 1942; and in 1943 a Personnel Relations Division Building, No. 400, and Paint and Sheetmetal Shop Building, Nos. 402 and 403, a part of Shop 70, were put up.

The buildings listed above by no means include the entire index of new buildings erected in the Yard during the emergency and war years, but they are specifically mentioned as among the most important new structures. With the new buildings in the vicinity of Drydock 8, already referred to, they are indicative of the type of expansion which was carried out. Scores of smaller buildings, storehouses, fire houses, locker and washrooms, tool houses, as already noted in the reference to temporary structures, were built during the emergency and war periods.

St. Helena

With the waterfront expanded as far south as it was practical to go, its further enlargement in that direction being blocked by the Norfolk-Portsmouth Belt Line Railway Bridge and the Jordan Highway Bridge, and the work load still growing, the Navy Yard management was faced at the height of the National Defense Program with the problem of obtaining more space in which to berth ships for repair and construction. Expansion of the waterfront northward was considered at several different times but only a small tract of land was available, the rest of the waterfront in that section being occupied by the Coast Guard station.

This property, a tract of slightly under two acres, lying between the Navy Yard's northern boundary on Lincoln Street and the Coast Guard station, was acquired in October 1941 from L. A. McAlpin and others at a price of $41,000. This expansion was completed with the acquisition from the City of Portsmouth in May 1942 of the portions of Lincoln Street and Henry Street flanking the property between First Street and the river, the City deeding the strips to the Government for a nominal one dollar.

Berth 1A was built on this property and the land area was used for ordnance and small boat storage space.

The talk of enlargement of the Yard to the north envisioned the taking over of the land lying between Third Street and the river extending northward to Wythe Street and the Seaboard Railway tracks. It was proposed that the old buildings standing on this property be town down and that housing for Navy Yard workers and Naval personnel be erected in their stead. This idea was dropped with the decision to develop the St. Helena annex across the river.

The old training station had been held by the Navy, as we have seen (Ch. V; Sec. 2), since 1846. It is probable that its name, St. Helena, in view of the naming of Portsmouth and Gosport for English seaports, was a corruption of St. Helens, another of England's seacoast towns. During the days when it had served as a naval training station, the old wooden frigates Richmond and Franklin had been moored there as receiving ships.

At this point it is interesting to note that one of the Norfolk Navy Yard's most cherished traditions is connected closely with St. Helena. It is the custom of firing the "Nine O'Clock Gun."

When Rear Admiral Stephen C. Rowan, USN, came to the Navy Yard as Commandant on September 4, 1866, after the Civil War, he ordered a curfew gun fired at 9 p.m. each night from the receiving ship. The custom became fixed, and it has continued to the present, with the exception of a short period between 1907 and 1909 when it was discontinued by order of Rear Admiral E. D. Taussig, USN, then Commandant, because it disturbed the commanding officer's baby at St. Helena.14

14 R. Adm. J. K. Taussig, son of the Taussig referred to, told the "true" story of the suspension of the gun after he became ComFive in an editorial in the Nfk.Ledger-Disp. 3 Dec. 1938, from which account the above is taken.

Loud protest came from the people of the community who had come to expect the sound of the gun each night and to depend upon it for the time. Despite pleas from the community, Admiral Taussig refused the restore the gun, but so determined were the citizens that they took their demands all the way to the White House where President Taft acceded to their wishes and order the gun restored.

The historic site at St. Helena offered possibility for development as an annex to the Yard and, when it became evident in mid-1941 that additional expansion was necessary, it was decided to turn the station into a ship repair Yard which would accommodate vessels of the destroyer, minesweeper and small classes. (Ch. IV; Sec. 6).

Work was begun late in 1941, and by the end of 1942 St. Helena was in full commission. General ship repairing facilities were provided with shop buildings, storehouses and piers being constructed.

Four piers each approximately 650 feet in length were built, adding a total of 23 additional berths. Branches of virtually all the Yard shops were set up so as to permit any type of work to be done with a minimum of delay. Thus equipped, St. Helena functioned throughout the war as a virtually independent repair yard.

Some 15 major new buildings were erected on the site. These included a boat shop, Bldg. 616; Sheetmetal Shop, Bldg. 617; Pipe Shop, Bldg. 618; Machine Shop, Bldg. 619; Shipfitter and Boiler Shop, Bldg. 620; Riggers Shop, Bldg. 621; Electric Shop, Bldg. 622; Transportation Shop, Bldg. 624; Paint Shop, Bldg. 648; Public Works Shop, utilizing the old Building No. 604; Storehouses, Bldg. 623; 657, and 658; a Power Plant, Bldg. 626; an Administration Building and Dispensary, Bldg. 625; and a cafeteria, Bldg. 645. Most of these buildings were erected in 1942, although a few were not completed until the following year. In addition to the larger buildings, a number of smaller buildings and temporary structures were also erected.

Transportation back and forth across the river between the Yard proper and the Annex was one of the problems which had to be ironed out. The Jordan Highway Bridge provided a direct link for the movement of vehicular traffic and heavy materials when St. Helena was first put in use, but ferry slips were constructed and ferry boats were subsequently provided as a more direct means of carrying the traffic. Motor launches and other small craft were utilized to transport personnel.

The Annex proved to be of great worth to the Yard for it was utilized soon after its opening for the completion and fitting out of the LSTs and DEs and YRDs built in the Yard. (Ch. X; Sec. 3 & 4). In addition it enabled the Yard to perform repair work on many smaller vessels and its facilities were constantly in use throughout the war.

The Coast Guard activities at St. Helena, consisting of shop and other buildings in the southern portion of the Annex, were not disturbed. Included in the Coast Guard end of the Yard are five finger piers for small boats, and occasional use of this pier space was made by the Navy Yard.

Further expansion of the Ship repair facilities on the St. Helena side of the river was also provided in the Fall of 1941 when the Bureau of Ships allocated funds for building a repair plant to be operated by the Norfolk Shipbuilding and Drydock Company adjacent to St. Helena. This yard includes piers, shops, a large floating drydock and other equipment for repair and overhaul of merchant ships. The Norfolk Shipbuilding and Drydock Company operated the Plant throughout the war on lease from the Government. This additional yard considerably increased the ship repair facilities on the Southern branch of the Elizabeth River and much Navy work was done there.

Barracks and Quarters

In addition to the expansion of the Yard's shipbuilding and repair facilities in 1940-41, the accelerated national defense program also brought about enlargement of the reservation to provide barracks areas for naval personnel attached to the Yard and for the crews of ships undergoing repair. Additional officers quarters were erected as well.

Prior to the Emergency, an old shop building in the central part of the Yard had served as an enlisted men's barracks. There were no quarters for bachelor or transient officers. The barracks building, No. 73, known as Sloat Hall, had formerly served as the Central Tool Shop, X06. It was converted into a Yard Craft Barracks through emergency relief funds in 1937. (N4(26)). This building could house 160 enlisted men and 16 Chief Petty Officers. A ship's service store was located in Building 31 across the street, the upper floor of which structure, known as Dale Hall, was used for dances by both Navy and civilian personnel.

The commissioning of many additional Naval vessels during 1940 brought the barracks problem to the fore.

A letter from the Commandant to the Chief of Naval Operations on October 16, 1940, (Ibid.) stated that there were then 365 men attached to the Yard Craft Barracks, including 104 from Yard Craft, the remainder being from vessels building, fitting-out or undergoing repairs. In addition, 102 men were under orders to report, and it was expected that many more would be ordered to the Yard for duty on other vessels then scheduled to arrive.

The situation was met in part by sending men on leave during their ship's availability, and by an arrangement with the Receiving Station at the Naval Operation Base whereby men were retained there until quarters could be provided instead of ordering them direct to the Yard as had been the practice. But a permanent solution to the problem was urgently required. Therefore the Commandant recommended that barracks and messing facilities at the Yard be increased. It was proposed that, if plans for a new central supply building and a new Administration building were carried out, it might be possible to house the enlisted men in one of the Administrative buildings -- 29 through 31.

During the first battleship modernization program, buildings at the St. Helena Training Station had been used for barracks. This expedient was not fully satisfactory, however, since the barracks were approximately one mile from where the vessels were undergoing work and water transportation was involved. When later vessels were modernized, the Department had provided other ships to be used as barracks for the crews, and in some cases men had been quartered in the Marine Barracks, but this facility was also overcrowded.

As a temporary expedient, it was recommended by the Commandant that a floating barracks should be set up. It was estimated that a vessel that could house and subsist 500 men would be satisfactory.

This idea was apparently prompted in part by a dispatch from the Secretary of the Navy on October 19, 1940 (Ibid.) suggesting that the Yard give consideration to chartering boats or renting other buildings for housing civilian workers.

To this end the Yard addressed letters to several steamship lines in the latter part of October 1940, including the Norfolk-Washington Steamship Company, the Old Bay Line, the Chesapeake Steamship Company and the U. S. Maritime Commission, requesting information as to the availability of vessels which might be used for barracks.

In addition, letters were sent to the Philadelphia Navy Yard and the Navy Department concerning the availability of several old Naval vessels, among then the HARTFORD, the "Damn the torpedoes, full speed ahead" flagship of Admiral Farragut at Mobile Bay, the OLYMPIA, Admiral Dewey's flagship at Manila Bay, and the BRIDGEPORT. Admiral Simons appears to have particularly favored assignment of the HARTFORD, the files showing a number of letters asking for its use.

It was pointed out that while these historic relic ships would be serving a utilitarian purpose, they would also serve a secondary patriotic purpose by their presence in Portsmouth, the plans being to berth them at a point where visitors could see and board the ships without being given access to the Yard itself. When the emergency ended they could be moved.

These proposals, however, were turned down by the Navy Department early in January 1941. In the case of each ship, the word from the Chief of Naval Operations was that the vessels were not suitable for the purpose.

In the meantime a number of privately-owned ships were offered, among them the Norfolk-Washington Line's SOUTHLAND, which was available to the Navy Yard for a rental of $166 a day, the Baltimore Steam Packet Company's STATE OF VIRGINIA, the Maritime Commission's ex-German liner, the GEORGE WASHINGTON, and the Hudson River Night Line Steamers' the BERKSHIRE and the RENNSELAER.

Instead of floating barracks, however, the Yard was advised by the Navy Department that barracks and messing facilities for 1,600 men and quarters for 75 officers would be provided. (Ibid; CNO endorsement Jan. 3, and 6, 1941)

To this the Commandant replied (Cdt. ltr to Chief BuDocks Mar. 17, 1941) "There is no space within the present limits of the Navy Yard for the construction of these facilities. It will be necessary to construct then either on the St. Helena reservation or on a site to be acquired near the Navy Yard,." The St. Helena site, being across the river, was not held to be suitable. The letter requested, therefore, that permission be granted for purchase of a tract of land lying to the west of the Navy Yard which was believed to be suitable for the purpose.

The Navy Department agreed to this purchase and on May 8, 1941, the Government received the title to the property from H. P. Barclay, a tract of some sixteen acres, forming part of what was known as the Barclay Farm lying within the triangle formed by George Washington Highway, State Highway Route 337, and Black Lane. The purchase price was $11,409.69. (See Real Estate Map, Sec. 6).

The development of the Groups B Naval Barracks area followed. Eight barracks buildings, an administration building, a mess hall, a recreation center and several smaller structures were erected. The first three barracks buildings were completed in August and the first occupants were housed in Group B on August 31, 1941. The other five barracks buildings were begun in September 1941, and the entire project was finished by early summer 1942.15

15 His.Notes, Naval Barracks, A12(3) gives detailed data.

The station's main recreation building, a brick structure housing a theater, ship's service store, gymnasium, bowling alley and other game rooms, is located in the Group B area. This building was dedicated in a special ceremony (Sec. 3) on July 1, 1942, at which the Governor of Virginia Colgate W. Darden was the speaker and in which other leading citizens took part. Subsequently many of the traveling USO Camp Shows played in its spacious theater, offering entertainment for the Naval personnel of the station.

Other recreational facilities were subsequently added at Group B: an indoor swimming pool, a pistol range, and an athletic field, and the entire recreation area was named Callaghan Center (Sec. 2) in honor of Rear Admiral Daniel J. Callaghan, USN, who lost his life in the Battle of Guadalcanal.

Late in 1941 the need for additional barracks and recreation space became manifest, and two additional barracks areas were constructed, one designated as Group A, to the west and south of Group B, and the second Group C at St. Helena.

For the Group A barracks a 62-acre tract of land lying along Paradise Creek was purchased from the Proctor and Gamble Company, for $54,750. This tract was, and is, completely separated from the Navy Yard, lying south of the Belt Line Railway and State Highway Route 337. Although the deed to this property was not recorded until August 7, 1942, construction began on the barracks buildings in January 1942.

This development consists of 18 barracks buildings, an administration building and a dispensary, a mess hall, laundry, commissary store, a recreation building and ship's service store, which was burned in December 1944 and not replaced (Ch. XII; Sec. 4), and auditorium, power house, and reservoir, sewage disposal plant, fire house and maintenance building, storehouse, incinerator, bake shop, and guard house, a swimming pool and an athletic field and grand stand.

The main part of the Group was completed on December 31, 1942, with the ship's service store and auditorium added in 1943. This recreation area was designated as Norman Scott Center honoring Rear Admiral Scott, USN, who, with Admiral Callaghan, was killed at Guadalcanal. The athletic field was named McCandlish Field, for Captain B. V. McCandlish, USN, who was captain of the Yard while the barracks areas were under construction.

Across the river, tying in with the development of the St. Helena Annex, the Group C area was constructed to provide facilities for crews of ships repaired on that side of the river.

This project consisted of five barracks, a mess hall and ship's service store, and several smaller buildings. Building 608, which had formerly been a storehouse after its period of use by the Naval Training Station, was converted to an administration and recreation center housing an auditorium, recreation room, chapel, library, barber shop and sick bay. This barracks area was completed in May 1942.

In 1942 and 1943 Bachelor Officers' Quarters were constructed in Bldgs 14 and 15, converted from warehouses, and a WAVE Officers' Quarters was built in Bldg. 19.

Expansion of Supply and Storage Areas

The increasing work load of the national emergency period placed a heavy burden on the already overcrowded supply and storage facilities of the Yard.16 By mid-1941 new buildings and waterfront development had taken up practically all of the previously unused areas in the Yard and additional space in which to expand was badly needed.

16 An excellent discussion of the NYNor storage problem is contained in "Wartime History of the Supply Corps." A12(3)

The land which was acquired for this expansion (N1(9)), with the exception of Berth1A and the naval barracks areas already mentioned, lay almost entirely to the south of the Yard. In all more than twenty separate parcels were purchased or leased between 1940 and 1943, but the overall expansion falls roughly into five major new sections: the barracks areas; the storage area in the vicinity of Bldg. 276; the Salvage area and Public Works lot between the Belt Line and Route 337; the Southgate Terminal Section; and the Navy Yard dump and incinerator area along Paradise Creek.

Each of these general new sections will be discussed briefly.

First is the area in the vicinity of Bldg. 276, (Cdt ltr to AstSecNav 19 Apr. 1941, FS/L9-3(87)"A"). Development of Group B Barracks had envisioned the taking over of the intervening land lying between Black Lane and Williams Avenue. Several owners were involved and four separate parcels were purchased, the Government getting all but a small portion of the property that was occupied by the Dixie Veneer Company.

First purchased was a tract of some 34 acres running from George Washington Highway and the Portsmouth City Limits on the north to a line south of Bldg. 276. Negotiations were opened for this tract with H. P. Barclay and some 25 other owners in the summer of 1941, but condemnation proceedings were necessary before the Government could get the title. The deal was finally consummated on August 15, 1941, with the owners getting a thousand dollars an acre, the total price being $34,379.

The second and third parcels were purchased from the D. H. Gowing Veneer Company, the first bordering Black Lane consisting of about seven acres on November 12, 1941, at a price of $7,260, and the second on September 5, 1942, consisting of slightly over ten acre as at the same price of $1000 an acre or a total of $10,253.

The last plot in the area, a small one of less than one acre, was leased from the Dixie Veneer Company March 15, 1943, for a nominal $1.00 a year. It was purchased December 6, 1944, for $6.00.

This new section of the Yard provided space for the new Supply buildings and outdoor storage, additional officers quarters and for a large parking lot.

The first building erected was a large general storehouse building No. 276, for the Supply Department, which was completed in March 1942. Three other Supply Department storehouses, Building Nos. 280, 423 and 424 were also erected, and in addition a building housing the Yard's oxygen manufacturing plant also occupies a portion of this area. Two storage buildings were under construction in this area at the end of the war.

North of Lee Street new officers' quarters, 11 houses in all, were constructed and the grounds landscaped. A large parking lot for civilian employees was built on the eastern end of the property.

The Salvage and Public Works lots, lying south of the Belt Line Railway and bordering on State Highway Route No. 337, were acquired in three separate parcels. The first of these, a tract of approximately 12 acres, was purchased on December 16, 1940, from the Portsmouth Company for $7,504.20. This formed the major portion of the present Salvage Yard, the eastern end of the Salvage Yard, a plot of some three acres, having been added in a purchase from the Savannah Creosoting Company on February 2, 1942, for $5,289.98.

The third parcel, which is now the Public Works lot and reservoir area consisting of some 11 acres, was purchased from the Portsmouth Company on December 31, 1942, for $7,554.35.

During 1942 and 1943 four acres belonging to the Norfolk-Portsmouth Bridge Company immediately east of the Public Works lot was leased to the Yard, but this lease was subsequently cancelled.

Two additional small plots in this same section of the Yard adjacent to the old Pershing Wharf extending beyond the quay wall at Berth 43, were also purchased. The first of these belonging to Arthur Hitch, was taken through condemnation proceedings on November 14, 1941, the owner getting $44,998.80 for slightly over three acres; and the second, less than 1 acre, being purchased on November 19, 1941, from the Norfolk-Portsmouth Belt Line Railway for $1,030.

Southgate Terminal was the fourth major area of expansion. The property was first leased by the Government in December 1940, and some storage use was made of existing buildings during 1941, but rental was considered too high, and the Government purchased the property in two parts, the first from H. B. Rodgers, operator of a storage and shipping business on these premises, the property being conveyed in a deed dated August 12, 1942. This section, consisting of 44 acres, was bought for $126,043.94. The second parcel was purchased from the Terminal Holding Corporation on October 13, 1944, $65,000.52 being paid for 39 acres. An additional plot of less than one acre was leased for one dollar a year from Allied Mills Incorporated on October 1, 1942.

Southgate provided the Yard with space for lumber storage and additional waterfront as well as with buildings for general storage and purposes. The existing buildings were added to, and new structures were erected. Five buildings are now available.

Although most of the Southgate waterfront was undeveloped when the war ended, the berthing space at the Allied Mills wharf was being used. Dolphins were placed in the stream and used for tying up a number of vessels.

In the vicinity of Southgate two additional tracts were leased, one for ship's storage, a four-acre plot leased from the Portsmouth Company in 1942 for $360 a year; and the other for lumber storage, some 10 acres leased from Savannah Creosoting Company on January 1, 1943, for one dollar a year. Lying between the lumber storage and Route 337, a six-acre parking lot was developed by permit from the Savannah Creosoting Company dated April 30, 1943.

But even these large expansions of space and facilities did not prove sufficient for the heavy war-time demands of the Supply Department, and in an effort to ease the storage problem an Annex to the Supply Department was acquired through lease of a waterfront warehouse adjacent to the Navy Landing in Norfolk. This Front Street property, formerly occupied by cotton merchants providing approximately half a million square feet of space, was leased from the Norfolk Warehouse Corporation on July 1, 1943, for $75.000 a year. Earlier on April 15, 1942, additional waterfront property had been leased from the Merchant and Miners Transportation Company at Boush and Main Streets, Norfolk, for $25,000 a year.

The final large new land acquisition adjacent to the Yard itself was the purchase from the Norfolk Dredging Company on June 5, 1942, of 65 acres lying along Paradise Creek for use as a Yard dump. An incinerator was erected in 1943 on the tract, which is bisected by Highway No. 681. Twenty-five additional acres leased from the Portsmouth Company for $1,125 a year, lying to the south, was returned to its owners and the lease was cancelled on September 15, 1944.

In addition to these major purchases and leases, additional small parcels were acquired by the Yard mostly in boundary areas, such as the strip along Gosport Road from the Fourth Street Gate to Green Street acquired from the Virginia Electric & Power Company in May 1943, for a nominal $1.00 for use as a parking area. A number of other permits, easements and agreements were made, usually with the State or County, for construction of roads, overpasses, railroad crossings, and similar uses.

One such permit to the Virginia State Department of Highways permitted construction of Highway 681 through the Navy Yard dump area, and a number of similar transactions involving small parcels were necessary in the Borum Overpass area.

Three small parcels were leased at St. Helena to round out the development there. (Full data on Real Estate Map following.)

Thus the total area of the Yard rose from 352 acres as at the beginning of the war to a total of slightly over 764 acres by the summer of 1943, more than doubling the reservation in two and a half years. It was at this stage of development that the Navy Yard stood on V-J Day.

Growth of Telephone System

Nothing more clearly indicated the tremendous speed-up of Navy Yard operations during the war than the expansion of the Navy Yard's telephone system. The functioning of this utility may be taken as typical of the increased services necessary all along the line.

In September 1939 the telephone system consisted of four manual switchboard positions, twelve local trunk lines, and 434 telephone instruments. No records are available as to the total number of call handled per day, but the cost of official and personal long distance calls amounted to about one hundred dollars a month. The total number of operators on the payroll in September 1939 was seven.

This manual system which combined Government-owned cable plant with leased switchboard trunk and station equipment was expanded(17) as the operations of the Yard increased and demands for services grew. In July 1945 the system consisted of 22 manual switchboard positions, four information positions, 70 local and toll trunks and 1,567 telephone instruments. An average of 47,278 calls were handled per week-day, and the total cost of official and personal long distance calls for the month of July was $5,377. Seventy operators were on the payroll.

17 A complete review of this growth is contained in a memorandum on the telephone system; 5 Nov. 1945, A12(3).

The two major problems which were confronted were those of obtaining sufficient equipment and keeping enough operators on the job. During most of the war the operating force was inadequate to handle the heavy traffic load. Since it was impossible to hire a sufficient number of experienced operators, learners were taken on and trained. Absenteeism was high. The situation was made more difficult by the necessity of maintaining 24-hour service, seven days a week, with a six-day work week.

Under the combined Government-owned and leased system, it is the responsibility of the Yard to furnish all wire connections between the telephone exchange building and the building where the telephone instruments are located. Installations of cable and outside plant were unable to keep pace with the demands. Improvised arrangements such as the connection of two or three instruments located in different buildings on the same line were resorted to. Insufficient cable and line facilities resulted in bad overloading and constant busy reports which slowed down operations.

Looking back, it is evident that the communication needs of the Navy Yard could have been served more economically and efficiently by the use of the dial system. The great bulk of traffic was between extensions within the Yard. The dial system would have handled this type of traffic automatically, reducing the operation force required by approximately 50%. More efficient service than that rendered by the manual system would have resulted.

However the telephone system, despite its lack of modern automatic equipment, like the other services in the Yard, did an almost impossible job and did it better than the circumstances indicated it would be done.

Indicative of the very large volume of traffic handled by the Navy Yard telephone exchange is the fact that the City of Portsmouth with approximately 14,000 telephones is said by officials of the Telephone Company to have a year-round average of approximately 100,000 calls daily, only twice the daily number of Navy Yard calls with approximately nine times as many instruments.

Summary

A list of the major new facilities begun and completed during the emergency and war periods follows:

FACILITY 1 Drydock 8 (New) 2 Co-op Restaurant, Bldg 265 (New) 3 Inside Machine Shop, Bldg 171, Northside Extension 4 Pier 6 (New) 5 Labor Board, Bldg 265 (New) Extent ions 1942 & 1944 6 Material Assembly, Bldg 268 (New) 7 Barracks B (New) 8 Paint Factory, Bldg 275 (New) 9 General Storehouse, Bldgs 276 (New) 10 Dispensary, Bldg 277 (New) 11 St. Helena (New) 12 New Officers' Quarters 13 Storehouses, Bldg 280 (All ff. new) 14 Group A Barracks 15 Group C Barracks 16 Berth 42 & 43 17 Shipfitter & Assembly Shop, Bldg 369 18 Oxygen Manufacturing Plant, Bldg 281 19 Field Shop, New Construction, Bldg 298 20 Storehouse, Bldg 297 21 Reservoirs 22 Berth 1A 23 Radio Material, Bldg 15A & Bldg 11A 24 Ordnance Storehouse, Bldg 278 25 Public Works Shops, Bldg 402 & 403 26 Salvage Storage, Bldg 372 27 Southgate Terminal, Bldg 377, 378, 379, 380, 381

382, 383, 384, All storage buildings28 Norman Scott Center, Bldg 363 29 Storehouse & Cafeteria, Bldg 424 30 Storehouse, Bldg 423 31 Storage Material for Ships, Bldg 408 32 Personnel Relations, Bldg 400 33 Incinerator, Bldg 431 The above list is not all-embrasive, smaller buildings and projects such as sub-stations and general improvements to streets, overpasses, (Ch. XX) etc., having been omitted. In April 1942, for example, more than fifty important projects were listed as underway in the Yard at one time (PWO Memo to Mgr., 28 April 1942 FS/L9-3 (87-79-MY)"C") with some seventeen others planned. Some projects were proposed and turned down, for example, a sewage disposal plant, which Admiral Gygax went on record against as not essential to the war effort (Ibid. Cdt. ltr BuDocks, May 1942). The list above, however, is representative and does include most of the more important new facilities.

Looking at the overall growth of the Norfolk Navy Yard during the emergency and war periods in retrospect, it becomes apparent that a substantial part of the Yard's expansion was either completed, underway or projected prior to Pearl Harbor.

A study of the table above together with the table of earlier improvements (Ch. V; Sec 6) bears out this point. It is true that, for the most part, the Yard's new land areas and many of the Supply and Storage buildings were added after the beginning of the war, but the essential shop and waterfront shipbuilding and repair facilities with which the Yard was to function during the war were in use when the war began or were put to use during 1942. In many respects the expansion was far-sighted, with the result that on December 7, 1941, the Navy Yard was not as unprepared for the role it had to play in the war as it might have been.

That is not to say that the Yard possessed all the buildings and equipment it needed at the outbreak of the war, for many new buildings had to be erected after the U. S. entered the war and construction in the Yard itself was pushed forward along with work on ships. Indeed in some areas construction work in the Yard hampered shipbuilding and repair; storage was inadequate, streets and roads were incomplete slowing transportation, and many other needed items had to be provided quickly. But in the main the basic facilities were in readiness or were soon put into use.

The present arrangement of the Norfolk Navy Yard, however, leaves much to be desired from the viewpoint of industrial efficiency.

Adding to an original layout, which in itself was not too well planned and faced with necessity of getting things done in a hurry during the emergency and war periods, the management was often forced to compromise between expediency and long range planning with the result that the Norfolk Navy Yard in many respects, like Topsy, "just growed".

Among the major faults which may be briefly noted, as a look at the map of the Yard will show, are the existence of the Marine Barracks and parade ground jutting into the middle of the most important shop area, taking up space that could be better used for industrial purposes; the extreme narrowness in the width of the Yard in the vicinity of the Administration Building, No. 33, which has prevented the proper expansion of administrative office space; the badly congested waterfront in the main drydock area which makes service to the docks difficult, Drydock 7 and 8 lying as they do between Drydocks 3 and 4; the existence of buildings on the waterfront, such as the Paint Factory, which have little to do with shipbuilding and repair, the lack of a centralized supply area adjacent to the waterfront and the location of major supply buildings at some distance from docks and piers; the divided new construction areas which are split between the shipbuilding way and Drydock No. 8; the existence of the Belt Line Railway and State Highway Route 337 with their bridges cutting the reservation in half; and the location of the St. Helena Annex on the opposite side of the river.

It is undoubtedly true that more productive work could have been accomplished had the Yard been better arranged. The individual shops and buildings erected during the war have been for the most part excellent structures. But from an overall viewpoint, many of them were poorly placed. The complicated physical layout of the Yard hampers the orderly flow of work and materials. For example, the Supply activities are scattered all over the Yard, the Supply Department occupying more that 60 different buildings.

The utilization of the old buildings in the northern portion of the Yard for purposes for which they were not designed - - administrative offices, the commissioned officers club, BOQ, WOQ, etc., has meant that these structures have been altered many times, with thousands of dollars having been expended on the changes, when the same funds might have been used to better advantage in erection of new buildings.

Among the most glaring of the Yard's needs throughout the war was for an administrative building designed for the purpose. The present administrative building, housing the Commandant's office, Industrial Manager's office, and other essential administrative offices, is an old warehouse-type building which was once a barrel factory.

The buildings in the old section of the Yard, notably Buildings 30 and 33, underwent many alterations during the war in an effort to adapt them to office use for Public Works, Machinery and Hull Drafting, Planning and Estimating, Supply Department offices, etc. Designed as warehouses many years ago, these buildings are generally considered to be inadequate.

The new land areas of the Yard to the south, which give the Yard's map a crazy quilt appearance, are separated from the Yard proper by intervening commercial property, and this together with the bisecting railroad and public highway has hampered transportation. The suggestion has often been heard that the area of the City bordering Third Street and Gosport Road could well be taken over by the Government to permit expansion of the Navy Yard beyond the limits of the ancient brick wall which now bounds the Yard in this congested section. It has also been suggested that the northern rectangle of the Yard be preserved as a Naval museum with shops and administrative activities removed to modern quarters.

Removal of the bridges has also been discussed, but their value to transportation has thus far outweighed the advantages to be gained by moving them.

It should be noted that the Industrial Survey Division of the Navy Department in its report on a study of the Norfolk Navy Yard made in December 1944 (ML 6 March 1945, A3(155-MA)) recommended the undertaking of a long-range development plan of layout that would be more conducive to industrial efficiency.

VII. YARD SECURITY

Air Raid Defenses

With the vast enlargement of facilities and thousands of new employees (Ch. XIV) coming in and with the Yard's exposed position on the Atlantic coast, one of the major considerations from the beginning of the emergency was for the security of the plant itself.

Three main problems were encountered: prevention of sabotage, maintenance of security of military information, and defense against possible attack. The Yard's Naval Intelligence unit working under cognizance of the Captain of the Yard was primarily concerned with the first two items and the Yard as a whole with the latter.

From the first of the emergency, the possibility of air raids was reckoned with. It was feared that because of the Navy Yard's strategic location and because of the extremely important nature of the work being done that the Yard might become the target for enemy attack.

Said Admiral Gygax on December 8, 1941, (CO 74/41): "The Norfolk Navy Yard, due to its importance in the Battle of the Atlantic, is an obvious target for Axis raids."

As early as the spring of 1940 plans were underway for defense measures particularly directed at the possibility of attack from the air in case of war. On November 4, 1940, in line with the speeded up defense preparations of those months, the Navy Yard underwent the first test blackout in its history. From that time until practice blackouts were eliminated in November 1944, air raid precautions were continued in force. (File A16(19)).

In the first weeks of the war, passive defense measures were increased and the Yard closed its gates to visitors (CO 23/39), strengthened its military security watch and increased police protection.

Two days after the outbreak of war, anti-aircraft units of the Coast Artillery took up positions for defense of the Yard and air raid precautions were speeded. The officers and men of the Coast Artillery units were quartered in the new barracks buildings, and antiaircraft guns were installed at various points in the Yard and at strategic locations throughout the vicinity.

Vital buildings with the Yard, such as the Central Power Plant, Sub-stations, First Air Stations, etc., were sand bagged to provide protection in case of raids, and an outer concrete wall was built for added security enclosing the main power plant. Buildings through the Yard were painted in a dull grey-green camouflage.

The Yard's Fire Department was strengthened and hand fire extinguishers along with sand and tools were distributed throughout shops and buildings to be used in case of incendiary raids. Air raid bills were drawn up, and instructions on what to do in case of attack were passed down to officers and civilian supervisors, and all employees were informed of measures to be taken in the event of raids. In addition roof spotters were placed in strategic positions, communications were strengthened and chemical warfare defenses were set up including the installation of a decontamination chamber.

The Yard, of course, escaped attack from the air or from any other quarter, but the war did come close in the first few months after Pearl Harbor. In the dark days of early 1942, sinkings of merchant vessels by German submarines on the Atlantic seaboard were common, and many survivors from these stricken vessels as well as some of the torpedoed ships themselves, were brought to the Yard.

Enlargement of Police Division

At the beginning of 1940, the entire Yard police force consisted of 36 men. The number increased rapidly, however, as the Yard expanded and as its security needs increased, and by the time of Pearl Harbor consisted of 223 patrolmen, with a total of 240 men in all in the division.

The police force reached it maximum strength in 1945 when a total of 306 men were listed on the roster. This large number was needed because of the expansion of the Yard which made necessary additional policing to take care not only of security but traffic control for pedestrians as well as vehicles and many other duties. New precincts were established at St. Helena, Southgate Terminal and at the Norfolk Warehouses used by the Supply Department, and in addition the division policed New Gosport.

As we have already seen (Ch. IV; Sec. 12), security watches are maintained throughout the Yard by Marines, with the naval barracks areas guarded by Blue jackets. During the five years 1940-1945, the manning of numerous gates, landings, buildings and the entire waterfront patrol were gradually taken over by the police to release Marines for more active duties.

Augmenting the police force during the war were a number of women who served as patrolmen, walking beats and performing other police duties when the Yard was unable to get men enough to do the job.

PART THREE: PRODUCTION

VIII. OVER-ALL WAR ACHIEVEMENTComparison of Construction, Repair and Manufacturing

Of the three phases of the Norfolk Nary Yard's productive activity in World War II (repair, new construction and manufacturing) repair was the largest in volume.18 Primarily the Norfolk Navy Yard is a ship repair Yard although the volume of other work is substantial.

18 For Navy Yard Policy, See OpNav ltr, 10 Oct 1940, FS/L9-3(87)"A"

A comparison of the productive work from the beginning of the war in Europe to the end of the war with Japan shows that of the total man days devoted to new construction, repair and manufacturing, 51% was in repair, 32% in new construction and 17% in manufacturing. Repair increased during the war and manufacturing decreased. In addition to this work, of course, was the Yard maintenance and other miscellaneous activities.

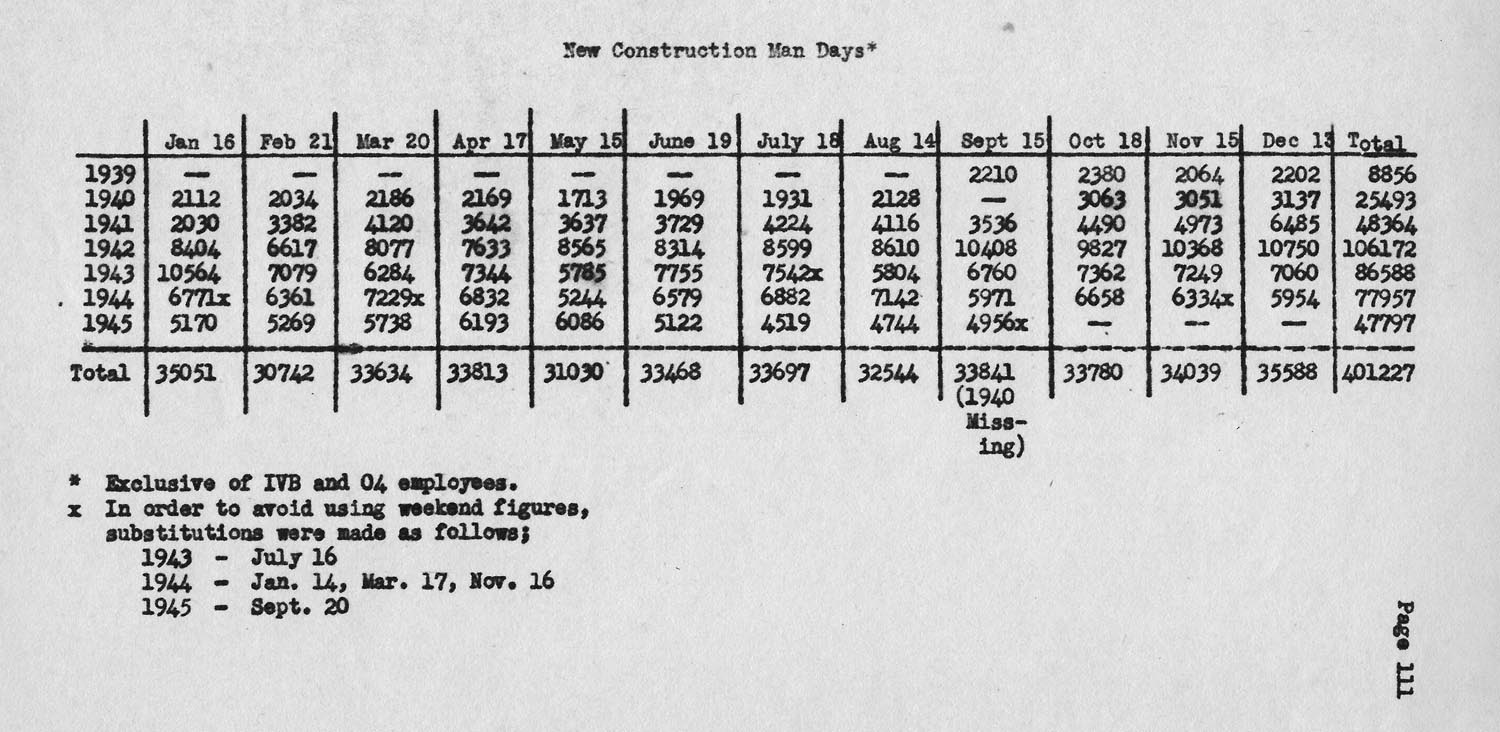

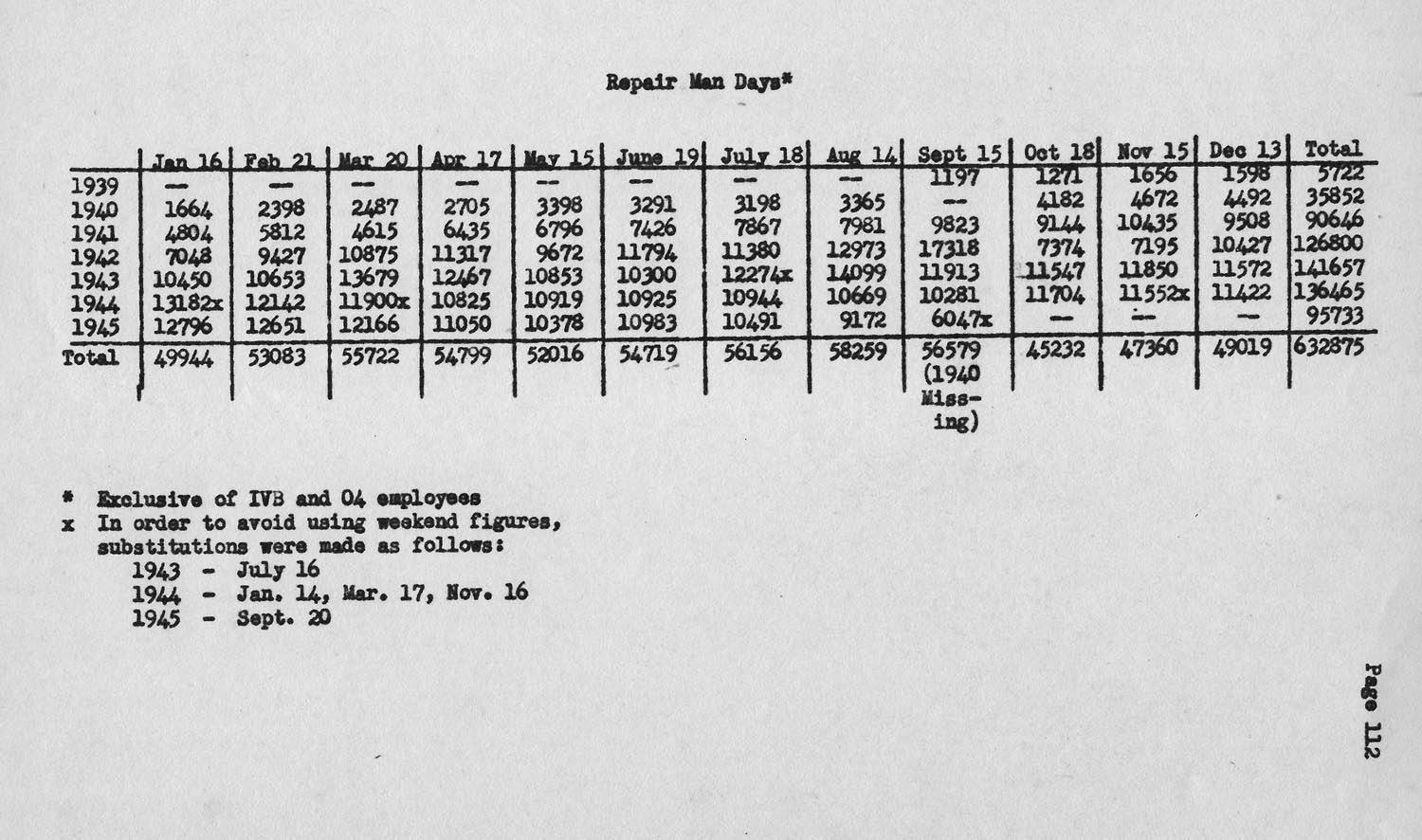

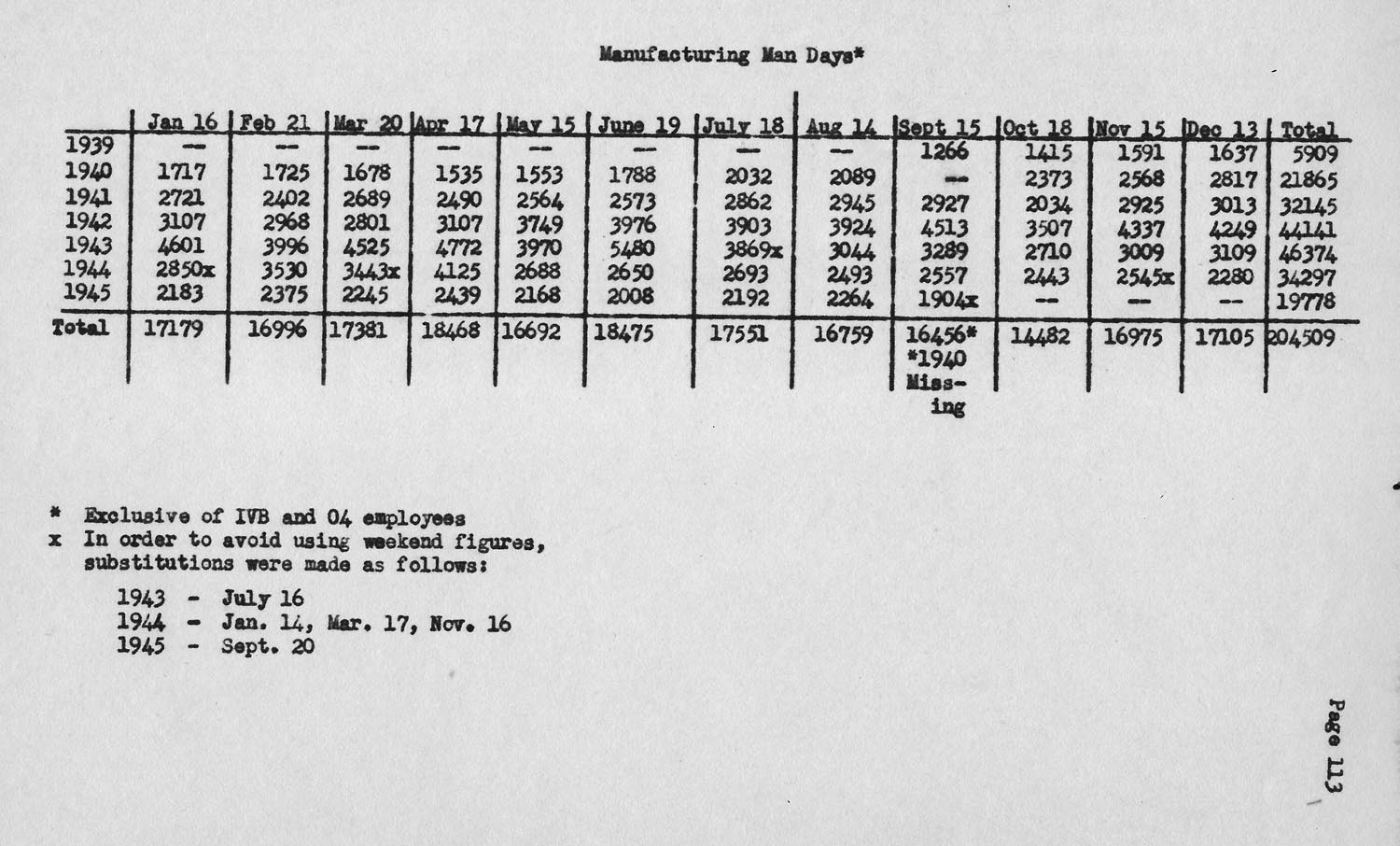

The figures varied for each of the emergency years as the following table will show: ("Total Man Days" means only for the one day a week checked.)

Comparison of Productive Workload

Total Man Days * New Construction, Repair and Manufacturing

1939** 1940 1941 1942 1943 1944 1945** Total * Exclusive of IVb and 04 employees

** 1939 - Four months (Sept thru Dec) shown

*** 1945 - Nine months (Jan thru Sept) shownThe term "new construction" is used to include those vessels built in the Yard and certain other vessels which were brought to the Yard in a semi-complete state for completion. The term "repair" is used to include also overhaul, conversion, modification, alteration and fitting out. The term "manufacturing" in the table above includes diesel engine, Title "Z" and "Z" manufacturing in shops from 1939 to August 1944; manufacturing, foundry and galvanizing, diesel engines, Titles "Z", "L" and "X" from August 1944 to May 1945; and from May to September 1945, manufacturing, foundry and galvanizing, arresting gear, turbine blading, diesel engines, metal furniture and other manufacturing.

The table above and those which follow showing new construction, repair and manufacturing man days broken down month by month, are based on figures obtained from Force Distribution records kept by the Production Division's Progress Section.

The Yard normally worked a nine-hour day during the war, increased from eight hours on June 21, 1943. (Ch. XVIII; Sec. 2) The actual number of hours worked, however, fluctuated considerably, and in order to facilitate record keeping, man days were used to represent numbers of men employed rather than periods of time.

Owing to the pressure of work in the Progress Section, only daily records were kept prior to 1945 and no compilation of figures was made. After careful examination of the records, it appears that a sampling covering a midweek day in approximately the middle of each month would be valid for purposes of comparison of the Yard's three primary functions.

These tables from which the preceding table was condensed follow:

(View tables in browser for best quality)

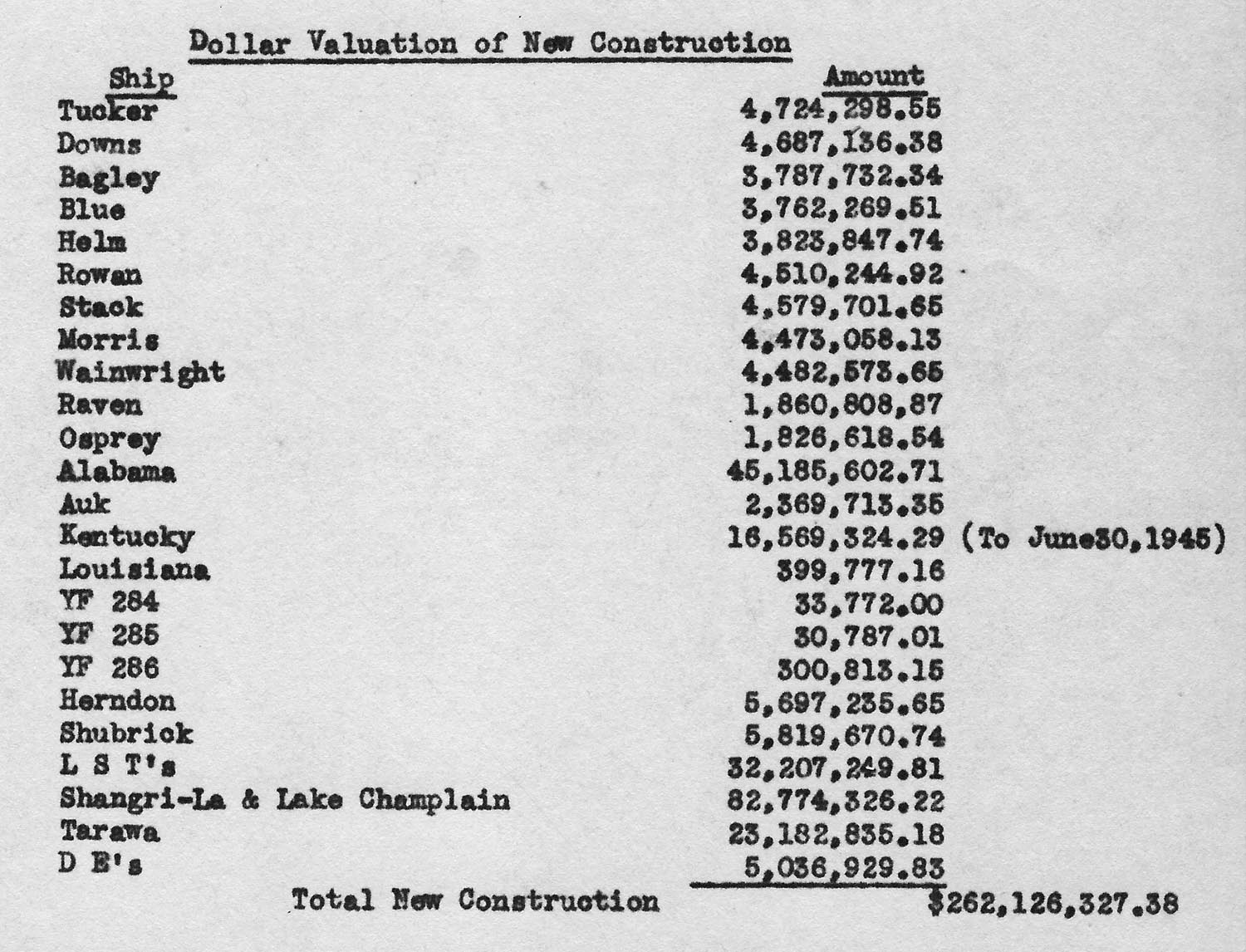

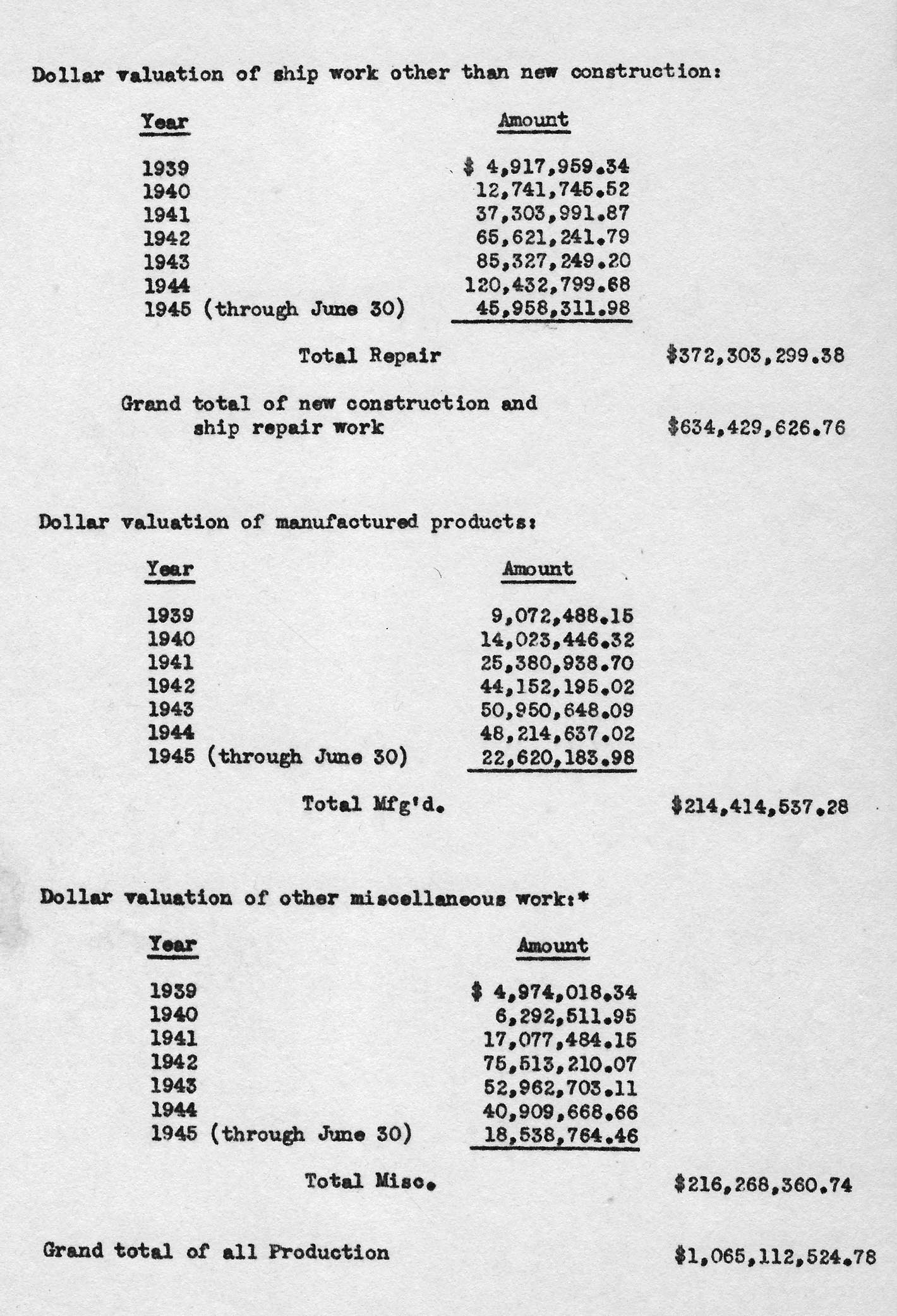

Dollar Value of Production

The value of the productive work done by the Norfolk Navy Yard in World War II was well over one billion dollars. The tables presented on this and the following pages show the comparative dollar value of new construction, repair, manufacturing and other miscellaneous work. (Figures taken from Acct. Dept. files)

In New Construction the dollar value of each vessel or combination of vessels is shown. It should be noted, however, that the figures cover only the cost of construction work actually done by the Navy Yard and are exclusive of Government-furnished items, such as ordnance gear and fitting out equipment, built elsewhere and simply installed in the Yard. The cost of the destroyers built during the Thirties is also included since it is believed that these figures are of interest.

* Note: The miscellaneous work listed in the last classification includes work for other government departments and special depositors performed under Naval Working Fund. There is also included under miscellaneous work repairs to APA material not in Naval Stock Accounts, materials in store, as well as considerable amount of other work such as construction repairs to targets, experimental and development work along with numerous other items charged to Title V. Title V is a miscellaneous title set up and used for the purpose of charging work of such nature that it could not be lodged against one of the specific ship or shore titles. There is also included in miscellaneous work all overhead expenses of the Yard which was charged directly to appropriations under Titles G and E. Title G is the over head expense title for all Navy appropriations except Increase and Replacement of Naval vessels. The pay of a large part of the Yard's Group IVb employees was lodged against this title and numerous other items such as repairs to buildings and transportation equipment and various items of waterfront maintenance work. Title H is the overhead expense for the appropriations for increase and replacement of Naval vessels. Included also was such ship work as repair of the Texas Oil Company's tanker S. S. MONTANA, (Ch. IX; Sec. 5), cases in which the work to be done was of interest to the government and the owners were unable to get it done elsewhere.

Accounting Controls

In connection with the dollar valuation of production, brief mention should be made of accounting controls.

In normal times when rigid control of funds must be exercised, management must have daily reports of the status of allotments promptly in order to anticipate need for additional funds, avoid over-expenditures and to determine whether physical progress of work is in line with expenditures. The expenditure reports coupled with daily force distribution reports provide satisfactory administrative control of funds and work.

During the six years of the emergency and war, accomplishment of the work was the major consideration and control of funds was not stressed. In order to reduce clerical work in the shops and Accounting Department, the Manager directed that expenditure reports be prepared on a weekly basis.

Owing to the lapse of time between expenditures, the report was informative but had practically no control value. The only control data available to Management during the war was the Force Distribution Report compiled daily by the shops.

There had been little change in accounting forms for several years until July 1, 1945. As of July 1, there was a major revision of the accounting system and accounting forms. An important feature of the change was the elimination 0f indeterminate overhead expense. Every item of expense after July 1945 was charged directly to an appropriation instead of being charged to a suspense account for later distribution of appropriations by the Accounting Department. This change tended to give the Bureaus better control of their funds than was possible before.

During the calendar year 1944, payroll procedure for per diem employees was changed from a rough payroll system to a weekly clock card system with clock cards as the rough payroll. (See also Ch. XVIII; Sec 1). One result of this change was the distribution of costs on the average hourly labor rater per week for each shop instead of the actual wage rate for individuals. The report of expenditures to management became a weekly report as a result of the change in payroll procedure and the manager's willingness to accept the report on that basis. No changes were necessary in report or payroll forms because of the changes in procedure.

Repair

Sixty-eight Hundred Ships

During the six years covered by the war and the national emergency, 6,850 ships underwent repair, overhaul, alteration, modification or conversion in the Norfolk Navy Yard. Of this number, 2,238 were placed in drydock. From January 1, 1940, when the first effects of war then beginning in Europe were being felt, to V-J Day, September 2, 1945, and the conclusion of hostilities in the Pacific, the displacement of vessels entering the Yard for repair totaled 27,470,669 tons.

Repair work for ship of the Fleet, as we have already noted, was the most important function of the Navy Yard during World War II. Throughout the war in practically every case, repair work enjoyed the highest priority, for it is obvious that a ship afloat is more useful than a ship under construction, and every effort was made to keep as high a percentage of the Fleet at sea as possible.

The following table clearly illustrates the tremendous volume of the repair load carried by the Yard during the war.

1/1/40 - 12/31/40 1/1/41 - 12/31/41 1/1/42 - 12/31/42 1/1/43 - 12/31/43 1/1/44 - 12/31/44 1/1/45 - 9/2/45 Note: The 1939 work load is estimated at approximately one million tons or less

* New Construction dockings are included.

For the complete and detailed breakdown of the repair load by months and ship types, see Appendix C.

The increase indicated by the above table should be noted. From a total of 446 ships in 1940, the number rose to 2,465 in 1944, an increase in the tonnage handled from 1,797,904 to 7,650,133. Dockings grew from 118 to 806. The peak year, as the table indicates, was reached in 1944 although 1943, on a basis of the total tonnage handled, was not far behind.

These figures speak for themselves. Obviously it would be almost impossible to detail all, or any great number, or the repair jobs accomplished. Typical jobs, however, as well as those of an unusual nature, will be referred to in the following.

Planning and Production Problems

The immediate burden of the war's unprecedented work load fell most heavily on the Planning and Production divisions.

In 1939 the Planning Division consisted of eight officers. The workload, both repair and new construction, was estimated at approximately 1,000,000 tons a year. Planning was performed relatively leisurely. Arrival conferences were often held a week after berthing of a shop and even more time elapsed before work was begun.

The Production Division boasted thirteen officers with three of them performing joint functions for Planning. The Progress Sections followed work through the shops and on the ships in a fairly routine fashion. Hot jobs came seldom. The total ship superintendent force consisted of three officers compared with the 77 carried on the roster at the conclusion of the war.

Increased personnel of these two divisions, but more important increased output per man, did as much to help carry the load as improved methods. As is true throughout the Navy, men were more important than machines.

As we have already seen, the Yard added a very considerable quantity of new machines and equipment, but to get the most out of this equipment required constant ingenuity particularly when it came to meeting availabilities on difficult jobs.

For example, parts were sometimes taken from one vessel to supply another on shorter availability; new items were sometimes designed when replacements were unattainable or involved too much time to procure; and even the Greyhound Bus Company was on one occasion called upon to supply a needed diesel engine. When feasible, not-to-delay-vessel-job orders were set up for partial repair if there was insufficient time to complete all of the necessary work.

Included in the numerous expediting techniques were the use of pictures instead of more complicated blueprints, the utilizing of sketches and memos in lieu of finished drawings, shortcuts such as verbal information and merely penciled memos, training of draftsmen, less detailed planning, acceleration in preparing specifications, procurement of phones for vessels under repair, and the use of special messengers.

Other speed-up practices included development of an extensive salvage system which made available parts which were frequently difficult to obtai, development of quick-drying paints which expedited docking schedules, and the repair of ships and machinery normally considered beyond repair to ease the pressure on new construction.

Many other means were used to expedite productions. Arrival conferences were placed on a twenty-four hour basis and despite little, if any, advance notice of a ship's arrival, work had to be begun within a few house after the initial conference. During the labor shortage from the summer of 1943 to the end of the war, subcontractors were used especially for electric motor repairs, special forgings, ammunition hoists, rigging items, and various ship parts.

In addition to these general problems, perhaps the most important point of all was the difficulty of anticipating most of the repair work which had to be done. Seldom did the Yard know more than a short time in advance what its repair load was going to be. Emergency jobs added to the difficulty of planning. Repair of battle damage, conversion of ships to new uses, work on scores of different types of vessels, and repair and alteration of a substantial number of unfamiliar foreign ships (Sec. 4) all complicated the repair picture.

CMP and Material Redistribution

The difficulty of obtaining critically short materials, coupled with the necessity of working against the pressure of time, made the Yard's procurement and supply problem particularly difficult. The necessity for close inventory controls and for building up stock piles adequate for scores of types of vessels was apparent almost from the beginning of the emergency

The inauguration in April 1943 of the Controlled Material Plan of the War Production Board applying to both repair and new construction eventually eased the situation.

CMP initiated a system of allocating and scheduling quarterly production of steel, copper and aluminum. The Navy Department apportioned its allotments granted by the WPB to its various programs in accordance with the war's demands. The Norfolk Navy Yard was, therefore, required as of April 1, 1943 (Mgr's Notice No. 16/43) to adapt its procurement and production to this plan in new construction as well as repair and conversion of ships. Estimates of material requirements were calculated quarterly based on past records of the Yard's work load and it future commitments.

The Yard's overall program was administered primarily at these coordinated levels: (1) Procurement of regular stock by the Supply Department, allotments authenticated by the Supply CMP Section. The Supply Department functioned as a commercial warehouse for its customer the Industrial Department, (2) Procurement of non-standard stock by the Supply Department, authenticated by the Supply CMP Section, assisted by the CMP Group of the Material Section (Industrial Department, (3) Supervision of shop production and enforcement of CMP regulations by Shop Superintendent's CMP Sections assisted by the Material Section CMP Group.